-

WELCOME TO THE TEAM, JOE STAUB, GENERAL MANAGER - CT

Meet Joe Staub, PTA Plastics’ new General Manager in Connecticut, whose leadership and passion for innovation are set to drive our team, and our customers, toward an exciting new chapter of growth.

LEARN MORE -

CHOOSING THE RIGHT PROCESS FOR COMPLEX DEVICES

Learn how choosing between insert molding and overmolding can impact your product’s durability, design, and manufacturing efficiency. Click below to read more!

LEARN MORE -

THE POWER OF PARTNERSHIP

Discover why open communication, shared goals, and trust are essential in custom injection molding and how our team turns collaboration into long-term success.

LEARN MORE -

THE RISE OF AUTONOMOUS SYSTEMS: CO-BOTS AT PTA PLASTICS

We explore how PTA Plastics is pioneering the future of plastic manufacturing by integrating autonomous systems and collaborative robots to enhance efficiency, safety, and innovation.

LEARN MORE -

WELCOME TO THE TEAM - TOM MURPHY, MANUFACTURING MANAGER

Announcing Tom Murphy, the new Manufacturing Manager at PTA Plastics! With a proven track record in streamlining operations and driving innovation, Tom is poised to lead our manufacturing team to new heights.

LEARN MORE -

INDUSTRY 4.0 AND SMART MANUFACTURING - THE INTEGRATION OF IOT

Explore how Industry 4.0 and the integration of IoT are revolutionizing the plastics industry. Learn about the benefits of smart manufacturing, enhanced efficiency, and data-driven decision-making that are shaping the future.

LEARN MORE -

BENEFITS OF ISO 13485:2016 CERTIFICATION

Achieving ISO 13485:2016 certification not only enhances product quality and safety in the medical device industry, but also boosts customer confidence and streamlines regulatory compliance. Read more below:

LEARN MORE -

EMPLOYEE SPOTLIGHT - JOEY LEACH

Our latest Employee Spotlight highlights Joey Leach - a dedicated Project Manager based in Colorado! Joey's exceptional leadership and commitment to excellence truly set him apart in our team. Click below to read more on this Employee Spotlight:

LEARN MORE -

STEEL MOLDS VS. ALUMINUM

We explore the key differences between steel molds and aluminum molds, shedding light on their respective advantages and applications in the industry.

LEARN MORE -

STERILIZATION AND CHEMICAL RESISTANCE

We explore the valuable insights into sterlization methods and chemical resistance considersations for medical devices. Our expertise in these crucial areas helps manufacturers ensure the safety and functionality of their products in healthcare settings.

LEARN MORE -

IMPROVING PART PERFORMANCE - THE USE OF GAS ASSIST

Gas assist injection molding is a versatile technique that helps produce hollow plastic parts with reduced material usage and improved strength. Click below to learn more:

LEARN MORE -

PAD PRINTING - AN OPTIMAL APPROACH

Discover the art and science of pad printing while exploring the versatility and precions of this essential technique in the world of plastic manufacturing.

LEARN MORE -

WHY CUSTOMER EMPATHY MATTERS - THE HUMAN CONNECTION

Discover the profound impact of customer empathy, where we delve into why understanding and resonating with customers' needs is crucial for building successful products and fostering lasting relationships.

LEARN MORE -

VALIDATION - IQ, OQ, PQ and ENSURING REGULATORY REQUIREMENTS ARE MET

We delve into the crucial aspects of validation and the significance of IQ, OQ, and PQ in the manufacturing industry. Learn how these key processes ensure the quality and compliance of our products while maintaining operational excellence.

LEARN MORE -

MEDACCRED - THE BENEFITS OF ACCREDITATION

We explore the significance of MedAccred accreditation in the medical device industry, highlighting the numerous benefits it brings to manufacterers and the overall quality of medical devices.

LEARN MORE -

EMPLOYEE SPOTLIGHT - BOB BERG

PTA Plastics is proud to shine the light on Bob Berg, a dedicated Employee-Owner with years of leadership and success, who is now the General Manager at our Colorado facility!

LEARN MORE -

MANUFACTURING CHALLENGES AND HOW TO OVERCOME THEM

Discover insights on tackling manufacturing challenges and explore effective strategies to overcome these obstacles and optimize your production processes for success.

LEARN MORE -

EMPLOYEE SPOTLIGHT - DESIREE ANTRAS

Join us in celebrating Desiree Antras, NPI Engineer at our Colorado facility, as a PTA Plastics Employee Spotlight recipient! Desiree's dedication and expertise in new product introduction shines brightly in our team! Click below to learn more:

LEARN MORE -

3D PRINTING AT PTA PLASTICS

With our expertise in Additive Manufacturing, PTA Plastics is dedicated to pushing the boundaries of innovation and delivering exceptional results for our customers.

LEARN MORE -

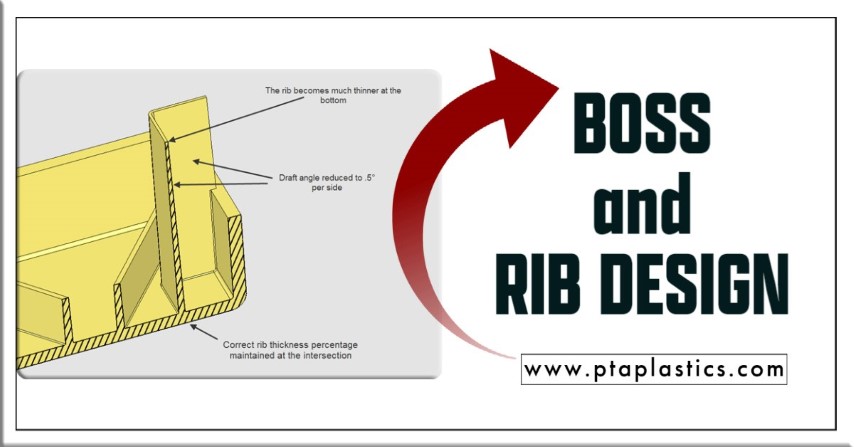

BOSS AND RIB DESIGN

In this post, we are diving into the intricate world of boss and rib design. Read how these critical features can optimize your plastic part design for improved performance and cost-effectiveness.

LEARN MORE -

THE COMPUTERIZATION OF MANUFACTURING

Learn about the transformative power of Industry 4.0, where we discuss the cutting-edge realm of computerization in the maufacturing industry. Discover how digital technologies are revolutionizing production processes and driving unprecedented efficiency gains in manufacturing.

LEARN MORE -

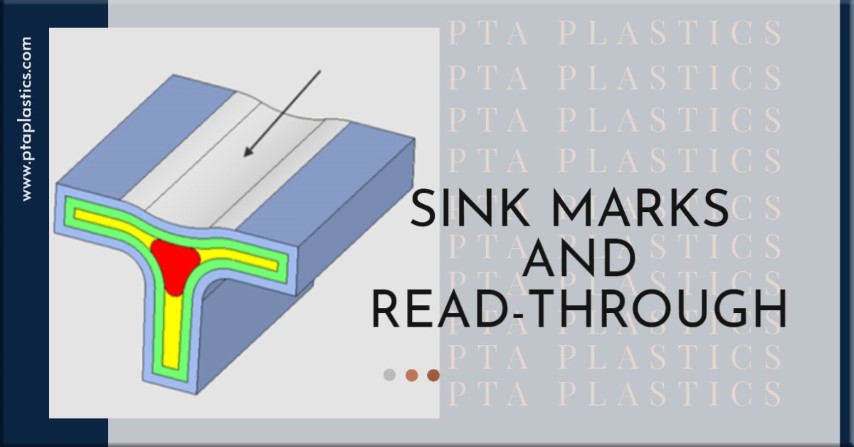

SINK MARKS AND READ-THROUGH

Sink marks and read-through are common challenges in plastic injection molding that can affect the quality and appearance of the final product. We go into detail on these issues, exploring their causes and providing insight on how to prevent and overcome them effectively.

LEARN MORE -

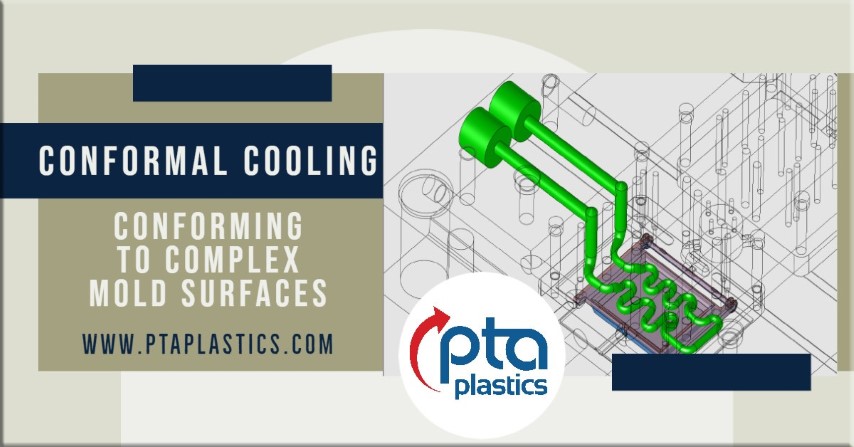

CONFORMING TO COMPLEX MOLD SURFACES

In this post, we dive into the benefits of conformal cooling in injection molding, emphasizing the ability to enhance cycle times and part quality. By conforming to complex mold surfaces, this advanced cooling technique optimizes heat transfer, leading to more efficient and precise manufacturing processes.

LEARN MORE -

AUTOMATION DRIVING RE-SHORING EFFORTS

We highlight how automation is playing a large role in driving re-shoring efforts, bringing manufacturing back to local shores. By leveraging advanced robotics and smart technologies, companies can enhance productivity, quality, and competitiveness, paving the way for a resurgence in domestic manufacturing.

LEARN MORE -

WHY ARE COMPANIES LOOKING TO RE-SHORE?

We discuss the growing trend of companies bringing their manufacturing operations back to their home countries. This post examines the reasons behind the shift, including improved quality control, reduced lead times, and the desire to suport local economies.

LEARN MORE -

WALL THICKNESS AND NOMINAL WALL

We highlight the importance of maintaining uniform wall thickness to ensure quality and consistency in final molded products. Read more by clicking below:

LEARN MORE -

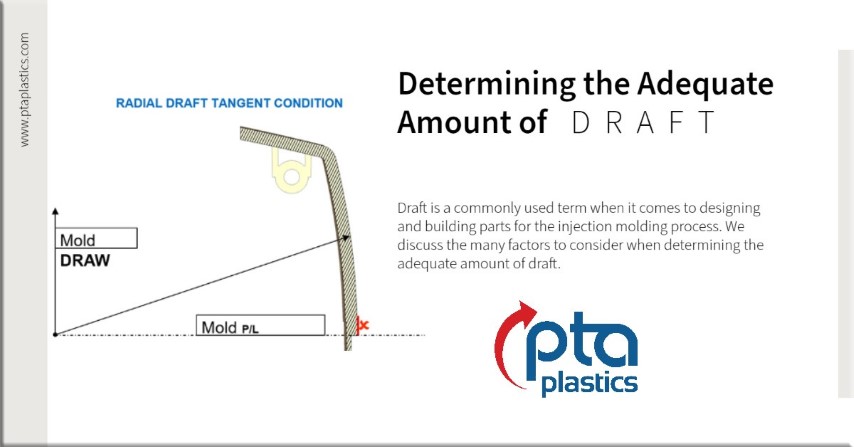

DRAFT AND WHY IT'S REQUIRED

Learn why draft is a crucial requirement for achieving high-quality injection molded components and ensuring manufacturing success.

LEARN MORE