Acclaimed Solutions

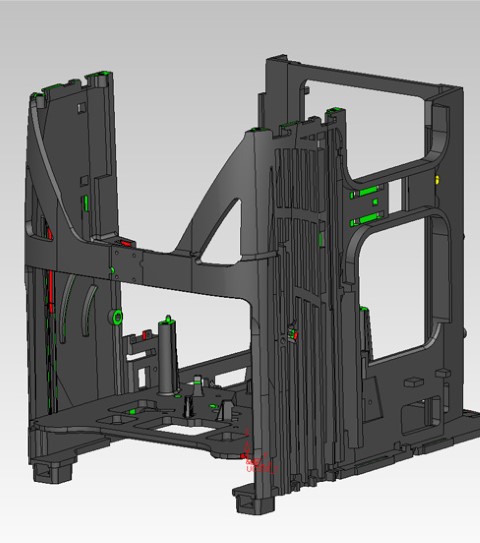

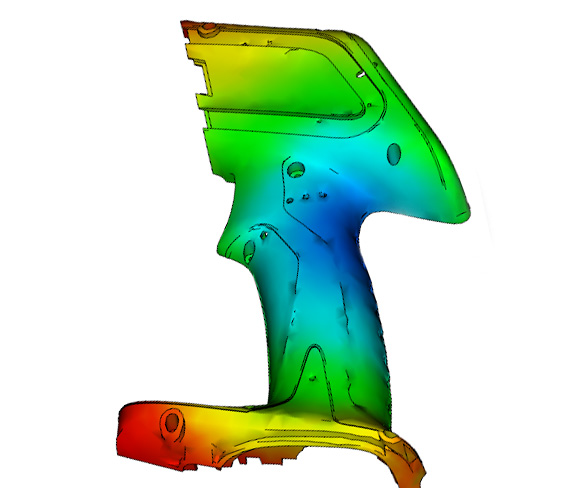

Our approach involves upfront collaboration with our customers, encompassing design, quality, cost, and manufacturability assessments, all before mold design begins. Furthermore, we carry out a complete Design for Manufacturability (DFM) review for all awarded projects, encompassing all facets of part design, mold design, and ongoing manufacturing.

The complete DFM also entails an assessment of wall thickness, draft angles, mold steel conditions, gate locations, mold actions, cost drivers, and a comprehensive flow analysis.

Have a question or a project in mind?

CONTACT USEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactOrganizations to excellent talent.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contact