Cost-Effective Solutions

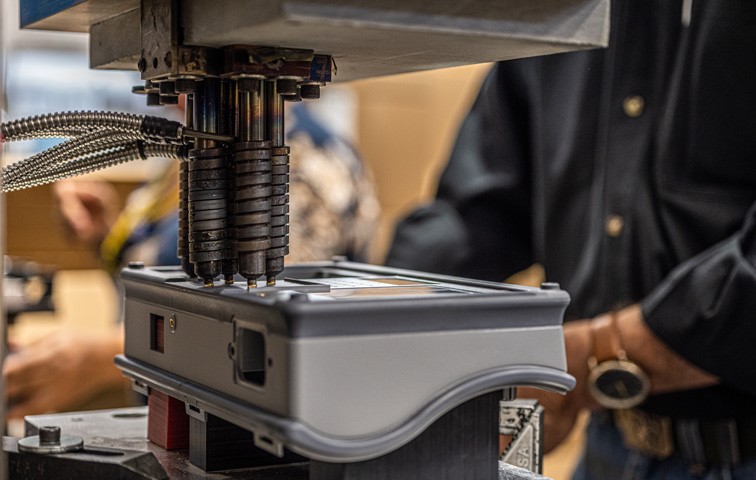

In addition to our primary services, we offer a comprehensive selection of secondary and value-added services. These include ultrasonic welding, insert installation (both heat and ultrasonic), assembly of molded and purchased components, pad printing, and heat transfer. Our primary goal is to offer our customers the most economical solutions available.

Have a question or a project in mind?

CONTACT USEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactOrganizations to excellent talent.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contact