A Full Process Validation Protocol

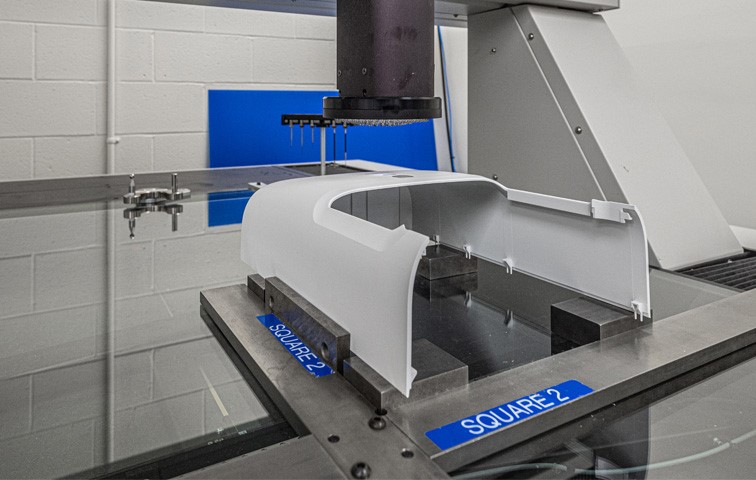

PTA Plastics provides comprehensive process validation in accordance with an IQ, OQ, PQ protocol. The determination of dimensions, CTF/CTQs, and proposed datum structures occurs following early customer communication and a formal print review.

Following the completion of the IQ report and establishment of the PFMEA, control plan, and process flow, our customers are presented with a formal process characterization report. This report highlights the scientific methods utilized to identify the nominal process, along with the parameters employed for process validation through Design of Experiments (DOE).

Have a question or a project in mind?

CONTACT USEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactEffective solutions for all business.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contactOrganizations to excellent talent.

Lorem ipsum is simply printing typesetting industry industry's standard dummy text printer scrambled ipsum is simply dummy text of the printing.

Get your first payment today and grow your business.

Explore services Quick contact