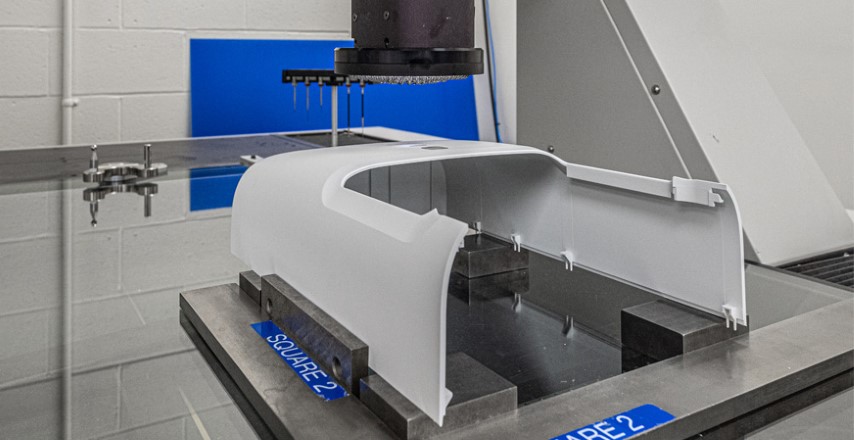

A Passion for Precision

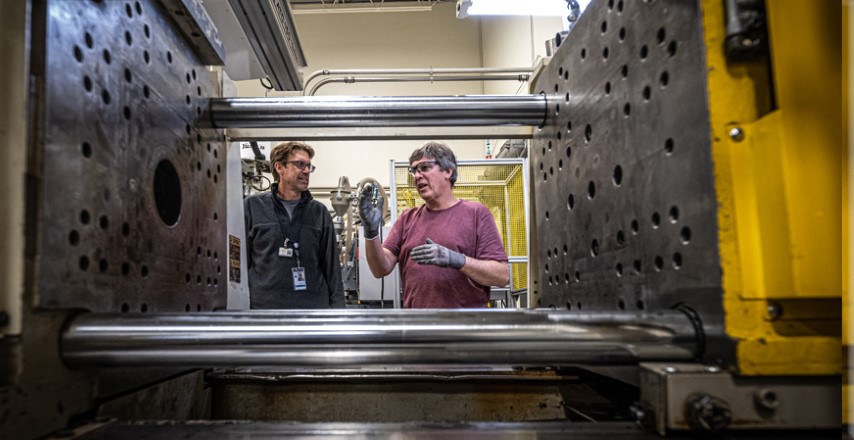

PTA Plastics is a solutions provider in the custom plastic injection molding industry, catering to high-mix production volumes with a wide range of product variations. Established in 1953, we operate from two locations in Oxford, Connecticut and Longmont, Colorado. Our company places great emphasis on transparency and assertiveness in project management.

PTA Plastics offers a seamless experience by working alongside skilled engineering teams specializing in new application development and maintaining an in-house tool room, allowing for high-end expertise without any hassle. By harnessing our profound moldmaking capabilities and a unified team of Employee-Owners, PTA Plastics specializes in serving the medical, defense, and safety and security industries.