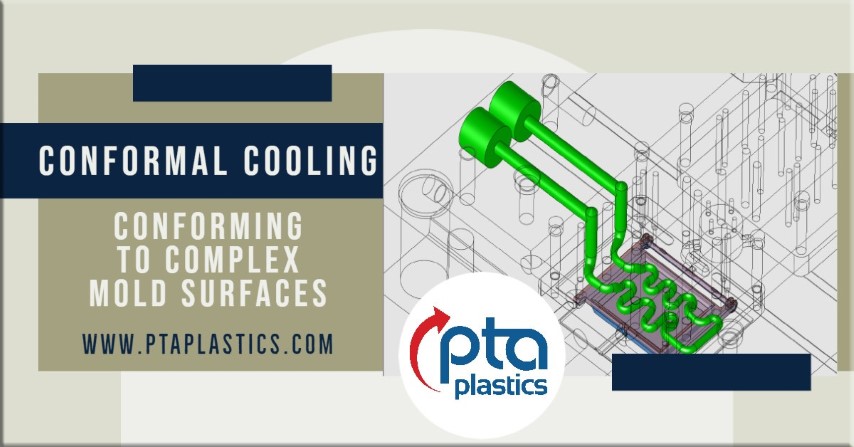

Conforming to Complex Mold Surfaces

Injection mold designers have been using a technique called “conformal cooling” for many decades. Mold temperature in the majority of injection molds is regulated through water lines (or steam or oil), which are typically drilled into the mold halves along straight pathways. However, this method limits the proximity of cooling to certain steel features. Conformal cooling, on the other hand, is an option that allows water channels to closely “conform” to complex mold surfaces.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) has made conformal cooling much more feasible in the past two decades. DMLS is an additive manufacturing technology that builds up geometries layer by layer, sintering each subsequent layer to the other. Another available technology is Selective Laser Sintering (SLS), which is distinct from DMLS but still a viable choice. Initially, these technologies were only viable for prototypes or low-volume applications. However, advancements in equipment and steel production now allow for mold components made through DMLS or SLS. What are the benefits of employing conformal cooling?

Conformal cooling is seen by PTA Plastics as an increasingly viable choice for a wider range of applications, and we have decades of expertise in this method. Tools that utilize conformal cooling require a bit more attention than traditional tools, which makes this particularly important. Plugged pathways caused by corrosion can be challenging to fix. PTA has purchased equipment to treat and descale cooling lines, minimizing the need for expensive component replacements. Having dealt with blocked paths before, we understand the importance of this issue.

We, at PTA Plastics, are committed to staying up-to-date with the latest advancements in 3D steel manufacturing techniques. These techniques not only enhance conformal cooling, but they also improve various aspects of injection mold manufacturing, such as lead times, component quality, and strength, among others. The speed at which change occurs is rapid, and our commitment is to maintain our position at the forefront of these changes as well as other emerging technologies.