Choosing the Right Process for Complex Devices

In the highly regulated world of medical device manufacturing, precision and performance are non-negotiable. Choosing the right molding process early in product development can save both time and cost while improving the reliability and functionality of your device. Two of the most powerful techniques used in complex plastic part design are insert molding and overmolding. At PTA Plastics, we specialize in both. Read more to understand what the differences are and which one is right for your application.

What is Insert Molding?

Insert molding involves placing a pre-formed component (typically metal or another rigid material) into a mold, where plastic is then injected around it to form a single, solid part. This process creates a strong mechanical bond between the insert and the molded material.

Common applications include:

• Surgical instruments

• Connectors with metal contacts

• Structural components with embedded fasteners or pins

Advantages:

• Reduces secondary assembly operations

• Enhances structural integrity

• Improves product reliability and performance

• Excellent for components requiring metal-to-plastic integration

What is Overmolding?

Overmolding is the process of molding one material over another. Typically, a base part, either plastic or metal, is produced first. A second material (often a softer elastomer) is molded over or around it.

Common applications include:

• Handheld diagnostic devices

• Wearable medical technology

• Grips, seals, and impact-resistant housings

Advantages:

• Improves ergonomics (soft-touch grip)

• Enables multiple material properties in a single part

• Allows for branding or color differentiation

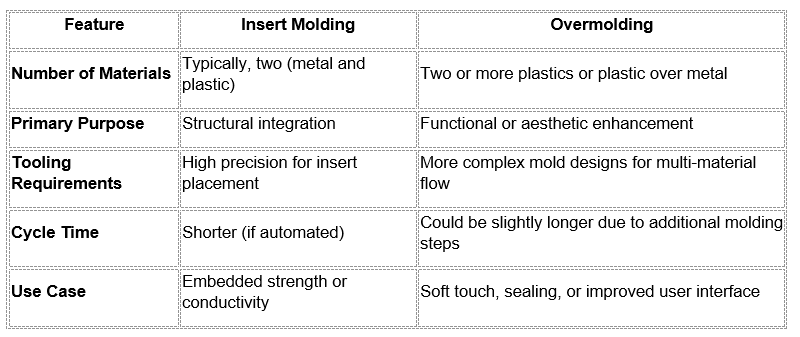

Insert Molding vs. Overmolding: Key Differences

Choosing the Right Process for Your Device

When determining which process is best for your product, consider:

• Functionality: Does your part need a rigid core (insert molding) or a soft-touch interface (overmolding)?

• Volume & Cost: Overmolding can be more expensive in tooling, while insert molding may save on assembly costs.

• Design Complexity: Our engineering team at PTA Plastics can help identify manufacturability challenges early in the design process.

At PTA Plastics, we bring over 70 years of expertise in precision molding for medical devices. Our in-house tooling, engineering, and quality assurance teams collaborate closely with customers to select the most efficient and effective molding process.

Ready to talk? Let’s determine the right path for your next complex device. Contact PTA Plastics today to request a quote.