Progressive Manufacturing Solutions

For over 70+ years, PTA Plastics is a leading custom injection molder, renowned for innovative solutions, precise engineering, and exceptional quality. With a rich history spanning several decades, PTA Plastics is a trusted partner for the medical, defense, and safety and security markets, delivering cutting-edge plastic components and assemblies.

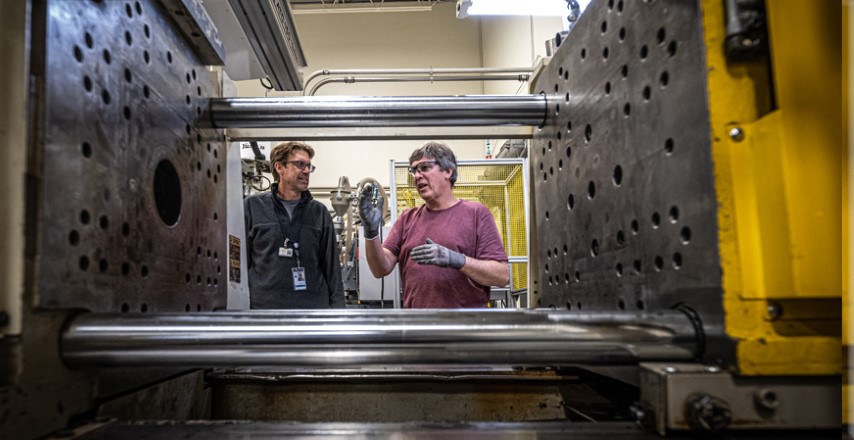

As an Employee-Owned company, we not only hold ownership over the organization, but we also prioritize the investment in the training, growth, and collaboration of new team members, allowing us to truly embody an extension

of our customers.