ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

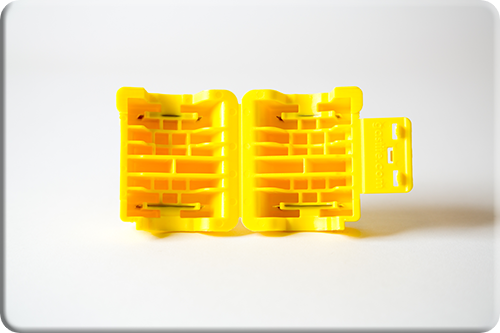

Over-molding continues to be an attractive option because of the functional flexibility it affords product designers and engineers. Using two separate plastic injection molds on the plastic injection molding press, two materials are bonded together during the plastic over-molding process to form plastic parts and components with unique visual or ergonomic appeal, such as handles or knobs. Custom plastic overmolding is also used to strengthen, protect and improve a part or end product, while reducing cost, labor and materials.

More often than not, the applications we see require a soft (elastomeric) skin bonded to a rigid substrate in products requiring a soft feel, vibration dampening or product protection. Over-molding has been widely used in higher volume applications where the cost of the specialized tooling, automation and molding equipment can be easily amortized.

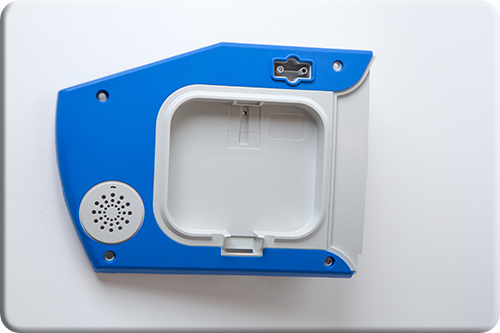

In addition to overmolding, we also offer insert-molding, structural foam and gas assist. Gas assist injection molding is the most effective method of applying pressure to an injection molded part, where the nominal wall cannot be maintained. It is also ideal for thick walled designs such as handles, as this process allows for pressure to be maintained during the cooling cycle. Gas assist injection molding is a low pressure process that utilizes Nitrogen, which reduces the clamp tonnage required for molding.

Structural foam molding (SFM) is similar to traditional injection molding whereas heated thermoplastics are injected into precision-made tools. The key difference between structural foam molding and injection molding is SFM is capable of producing much larger sized parts with lower molding pressures.