ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

Founded in 1953 with two facilities – in Oxford, Connecticut and Longmont, Colorado – PTA Plastics takes tremendous pride in being transparent and aggressive in project management. We are a niche low/medium volume, high mix custom plastic injection molder. Together with skilled engineering teams focused on new application development and an in-house tool room, PTA Plastics removes the hassle and adds high-end expertise. With deep moldmaking competencies and a cohesive, tight team of Employee-Owners, PTA Plastics focuses on the medical, defense, and safety and security industries.

We're invested in the training, growth, and collaboration that make us a true extension of our customers’ teams.

Starting with customer collaboration, PTA Plastics’ full Design for Manufacturability (DFM) review for quality will ensure your project’s continued success.

LEARN MORE

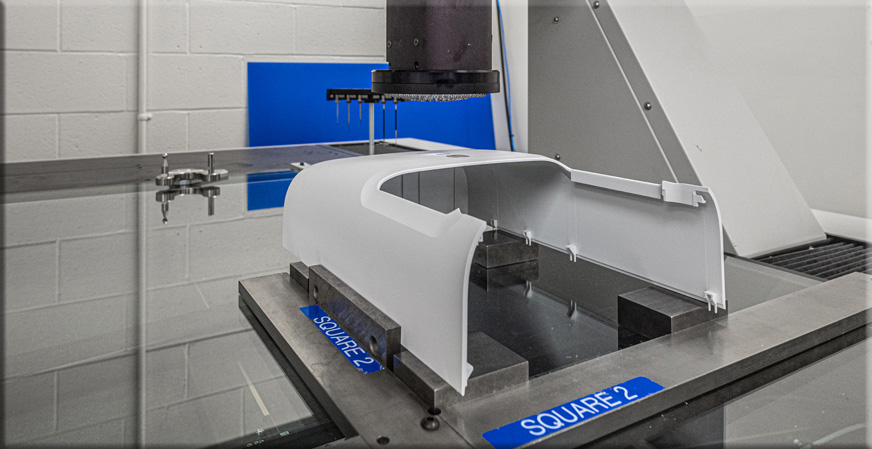

We utilize state-of-the-art CNC and EDM technologies with fully equipped mold shops to tackle projects both large and small.

Our molding presses range from 30 to 1,235 ton capacity, with unique 1-piece flow production cells for cost-effective operations.

We provide our customers cost-effective solutions while offering a wide array of secondary and value-added services such as ultrasonic welding, installation of inserts, assembly, pad printing, and heat transfer.

LEARN MORE

Our complete ISO standard validation protocol is included in all tooling, and it is fully customizable to fit our customers’ needs.

PTA offers a handful of specialty molding process including over-molding, insert- molding, and structural foam/gas assist. Benefits include cycle time reduction, resin savings, and improved part quality.

LEARN MORE