ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

ISO 9001:2015 | ISO 13485:2016

PTA Connecticut (203) 888-0585

PTA Colorado (303) 652-2500

With an emphasis on the medical, defense, and safety and security markets, PTA Plastics will help you find the solutions you need for your thermoplastic products. We take the time to ask the right questions and uncover any potential challenges to ensure a smoother, more reliable finish.

We are an Employee-Owned company, meaning our team not only owns the company, but we invest in the training, growth, and collaboration of new team members to make us a true extension of our customers.

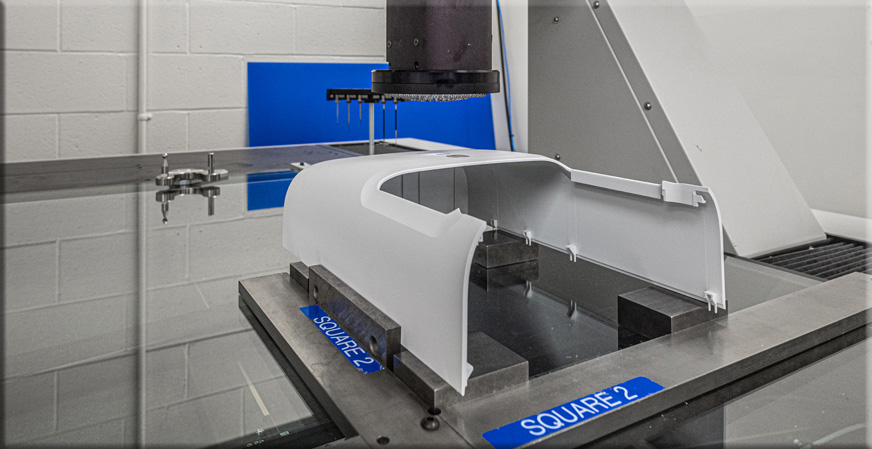

CREATING PRECISE PRODUCTS

CREATING PRECISE PRODUCTS

PROJECTS MADE IN AMERICA

DETAIL AND PRECISION

QUALITY PROCESSES

SKILLED ENGINEERING

TOOLING SOLUTIONS

INNOVATIVE PRODUCTS

NEW APPLICATION DEVELOPMENT

HIGH-END EXPERTISE

REVOLUTIONARY MOLDING SOLUTIONS

Founded in 1953 with two facilities – in Oxford, Connecticut and Longmont, Colorado – PTA Plastics takes tremendous pride in being transparent and aggressive in project management.

We take satisfaction in our strong knowledge of material and aesthetic standards to help ensure your only shot at submission is a success by providing quality T-1 parts that save time and money by eliminating up-front complications.